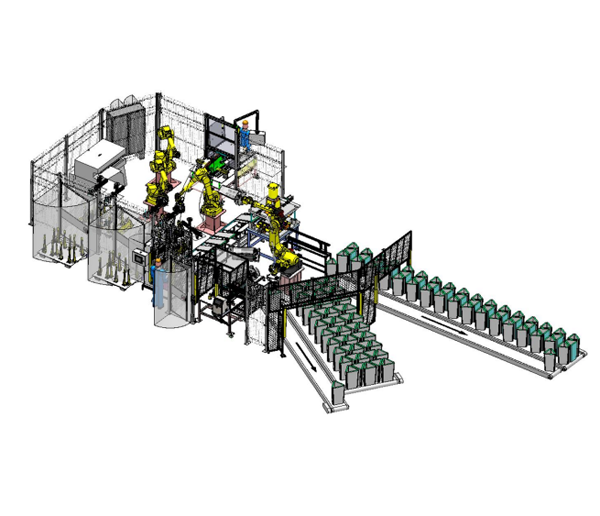

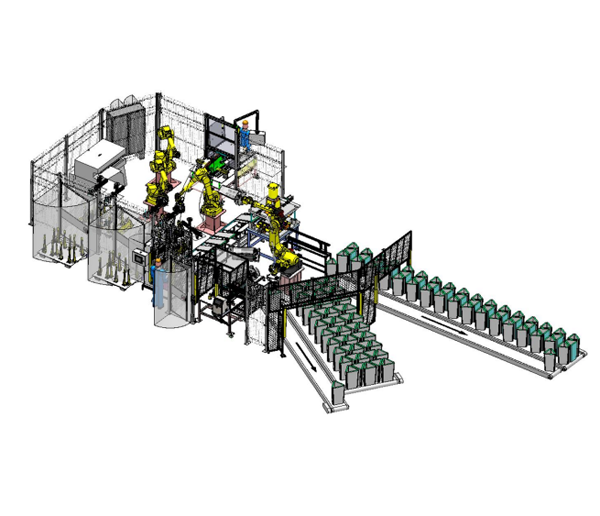

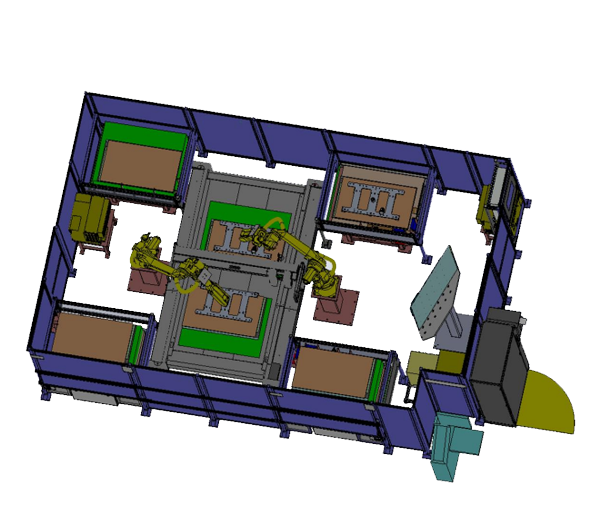

Standard Manufacturing Weld Cell

The company we worked with in this case wanted to create a flexible manufacturing solution for its production equipment.

ACRO Automation Systems Inc. approaches every project and every client with care. The team is always ready to provide expert automation solutions. You can browse our case studies to get a better sense of the vast assortment of products, services and systems this company has to offer. You will find a variety of past successes that characterize ACRO’s absolute dedication to quality.

The company we worked with in this case wanted to create a flexible manufacturing solution for its production equipment.

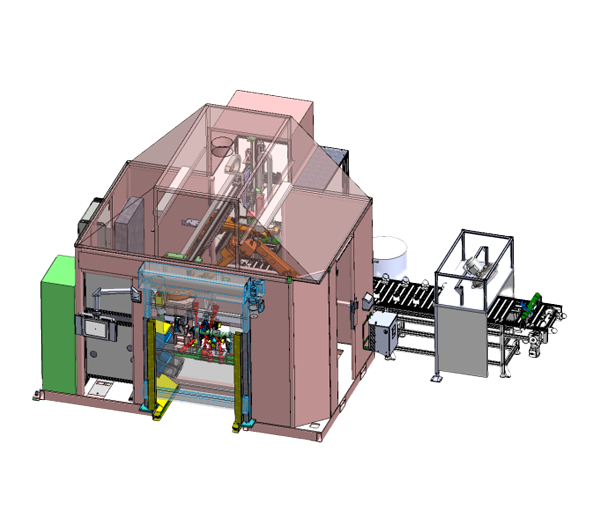

In the following case, the client was a seating component supplier to OEM automotive customers.

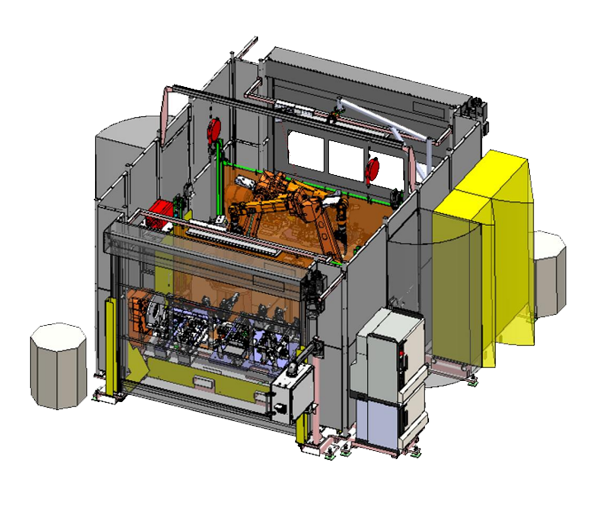

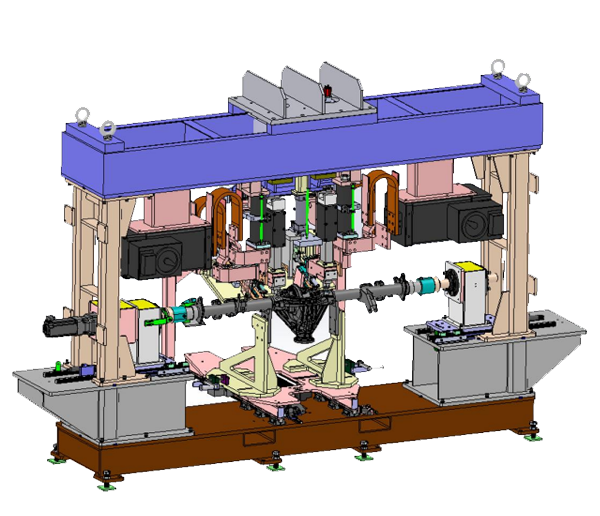

In many cases, clients wish to modify existing products and processes in order to increase their functionality or productivity.

Providing automation solutions often involves adapting automation systems to meet customer needs.

This premier global axle manufacturer needed an automated assembly to meet the complex tube press and welding demands created by the design.