Manually applying sealant for assembly often lacks precision due to fatigue and carelessness, leading to inferior products. This is problematic when fulfilling orders and pleasing customers. Robotic dispensing ensures consistent, high-quality parts, saving time, money, and maintaining customer goodwill. Embracing automation can elevate your company and provide a competitive edge.

Enhance the quality of your products when you utilize robotic dispensing machines in your facility. Consider these five benefits:

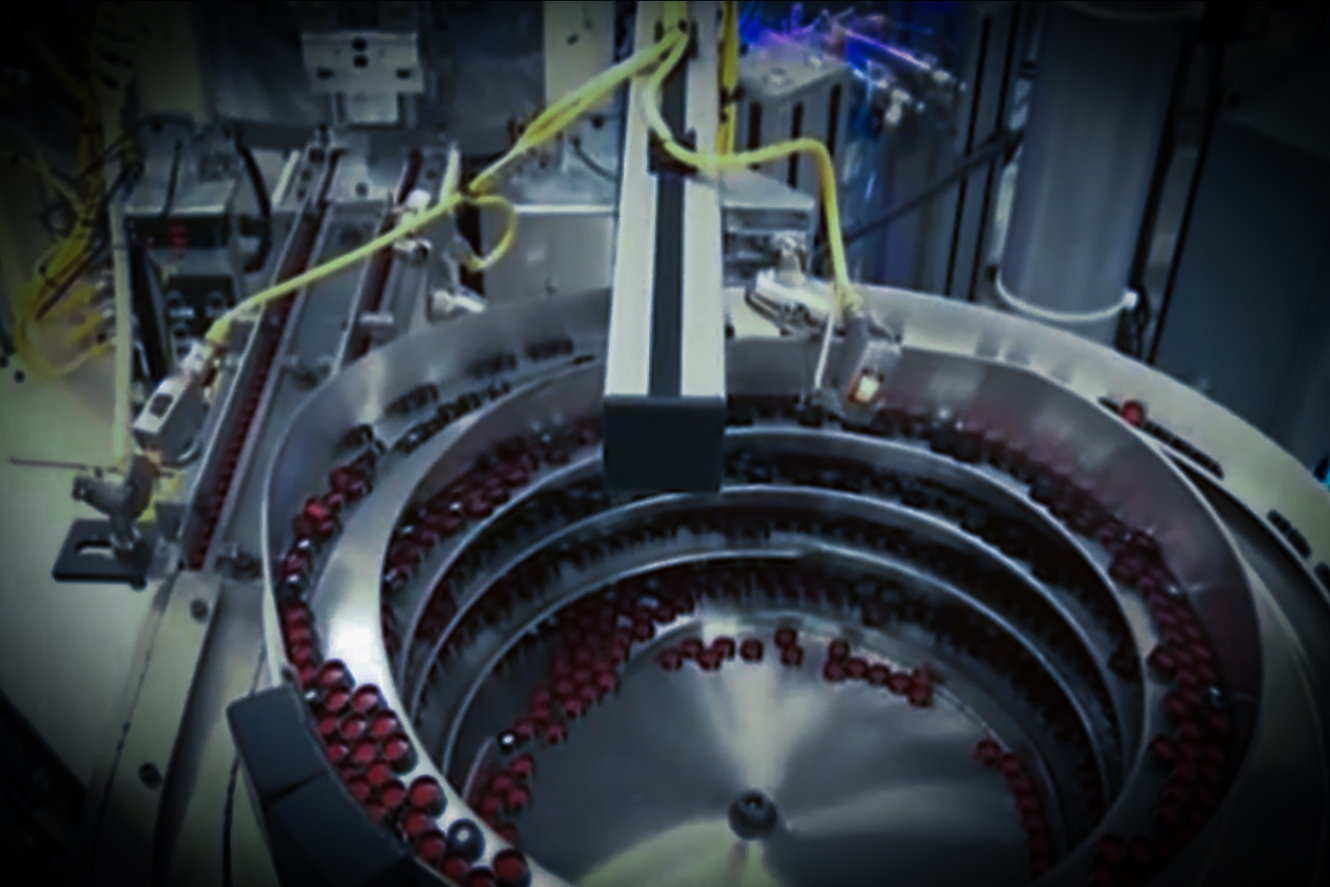

Robotic dispensing takes the inconsistency that can occur with human applications and removes it from the equation. You are left with beading that is appropriately positioned and is the correct width and height.

Robots will run 24/7, alleviating the need for breaks and downtime. You will be able to get your products out the door on schedule.

You can depend on only the precise amount of material being released; thereby, saving material and money while practically eliminating the need for manual corrections.

Your team does not have to be directly exposed to hazardous materials that often come with some applications, such as sealants and glues.

By having the material placed accurately, you produce quality products consistently and reliably. Your customers will know they can rely on you to create the best parts for their applications.

The applications are varied and include:

Obtain uniform coverage and complete adhesion with clear and black primer for windshields, roof modules, or other applications.

Robots provide an accurate application of lubricants like mineral oils, lithium grease, or dry film in hard-to-reach openings of your parts.

Increase the ability of your parts to bond effectively by dispensing the proper media for bonding. For example, you may use robotic dispensing for alcohol wiping, a plasma plume, or gas flame etching.

Once two surfaces are prepared, they need to be bonded with accurately dispensed adhesive. Whether you use cyanoacrylate adhesives, hot melt, silicones, or other substrates, you will enjoy consistency in the dispensing process.

Do you have a project with complex geometry that needs accurate application of foam, sealant, or urethane? Utilizing a form-in-place gasket will aid in reducing labor costs while improving the quality.

Discover our extensive collection of automotive case studies and explore our comprehensive video playlist showcasing the exceptional machines we’ve built. Click the buttons below to learn more and see our innovations in action.

Robotic Dispensing

Systems Video