Industry:

In many cases, clients wish to modify existing products and processes in order to increase their functionality or productivity. In this case, a large automotive company sought to improve the quality of their product as well as the quality of the product’s component parts. The customer also wanted to improve their production process. Read on to see how the team at ACRO Automation Systems Inc. devised the right solution for this customer.

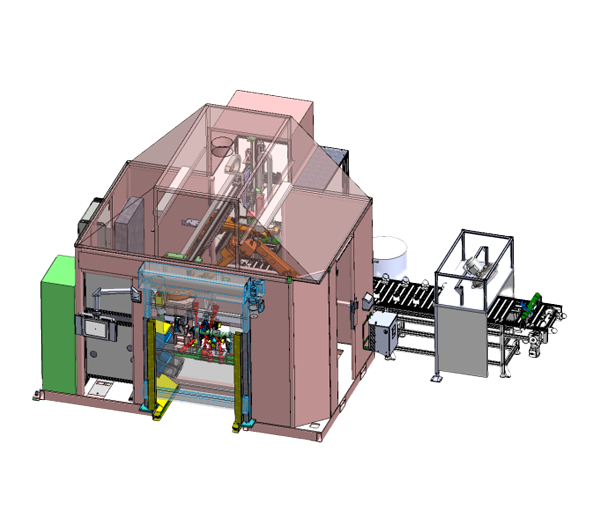

Often, much of what we do at ACRO relates to making improvements on existing equipment. Below, you will see the way that our team worked to achieve the client’s objectives:

Processes

The involved processes included robotic welding, material handling and flexible manufacturing.

Company Background

The customer is a large automotive company that produces pick-up truck rear axle assemblies, with plants worldwide.

Challenge:

The client had set up company-wide initiatives to improve the quality of their product and its component parts. The company wanted to increase the capability of the equipment. Specifically, their goal was to increase the repeatability of the dimensional location of the brackets that are welded to the axle tube. Due to the large amount of weld on the tube brackets, they were distorting and moving after they cooled. The customer was looking for a more repeatable process that would give the product increased variance.

Assessment:

Their former process was to weld the flange onto the tube first, and then, in the very next cycle, to move the sub-assembly to the bracket. This welding process puts a great amount of heat into the assembly, which subsequently contracts and moves as it cools.

The ACRO team provided consulting and engineering services to evaluate and test new manufacturing concepts with the goal of producing a more stable, quality part. Also, part of the scope of the work was to conceptualize the next manufacturing line that the company would buy for their future axle tube program. The team took the following steps to reach the end results:

01

ACRO concluded that the brackets should be welded onto the tube before the flange is attached.

02

There should be plenty of time between the welding of the brackets and the welding of the flange, allowing the tube time to cool and stabilize.

03

The system was transformed into a multi-station, automated line. A pallet conveyor was utilized between operations with a buffer that was ample enough to allow the part to cool.

The new axle tube bracket weld lines are now producing better quality products than in the past. The initial manufacturing study to improve the product was well worth the time and effort, and the project was a success for both the customer and us.

After the concept was sent out for competitive bids, ACRO was awarded the opportunity to design and build the equipment. Thus far, we have built four lines for this company.